Frozen period, From

Frozen period, FromRun the Perform lead time planning process to calculate the planning for one or more production files. This will automatically schedule the operations specified in the production file using the Operations button. If the production file includes any parts, equipment, or external operations that are linked to an operation, those items will automatically be scheduled as well.

When performing the planning calculations, you have two options:

The underlying files can be scheduled at the same time.

The scheduled operations can be displayed on the Gantt chart tab of the Production calculation for operations form. The planning can be changed manually, canceled (dropped), or re-performed. The calculated lead time planning therefore does not need to be final.

Note: Personnel schedules are not used for the Perform lead time planning process. Scheduling takes place based on the available capacity of the capacity group specified on the operation line.

For more information on the way Isah calculates the planning of production files, see the Planning topic in the Processes in Isah section.

Fields

Production status/date

These fields can be filled in only if you chose selection by production status/date. If these fields are left empty, everything will be selected.

The Frozen period and From fields are linked:

Current date + Frozen period = From

If the frozen period is set to '0', no 'From' date is filled in. This date can then be specified at a later stage. Even if the 'From' date has been filled in using the above calculation, you can still enter another date, if required.

When scheduling forward, the period 'From' - 'To' applies to the start date of the production file. This means that only production files with a start date falling in the selected range will be scheduled. When scheduling backward, the period 'From' - 'To' applies to the end date of the production file. This means that only production files with an end date falling in the selected range will be scheduled.

These fields can be filled in only if you chose selection by production status/date. If these fields are left empty, everything will be selected.

The Planning horizon and To fields are linked:

Current date + Planning horizon = To

If the planning horizon is set to '0', no 'To' date is filled in. This date can then be specified at a later stage. Even if the 'To' date has been filled in using the above calculation, you can still enter another date, if required.

When scheduling forward, the period 'From' - 'To' applies to the start date of the production file. This means that only production files with a start date falling in the selected range will be scheduled. When scheduling backward, the period 'From' - 'To' applies to the end date of the production file. This means that only production files with an end date falling in the selected range will be scheduled.

Planning direction

Forward, Backward, Start date, End date

Forward, Backward, Start date, End date

If you choose to make a selection by production file/order, the start and end dates will be copied from the selected production file. You can change the data, if required. When scheduling forward, a start date is required, and when scheduling backward, an end date is required.

When selecting by production status/date, there are two possible situations:

Note: A special situation occurs when the current date is used as the start date, in combination with confirmations on the same day. As a result of the confirmation, the load will be removed and capacity will be freed up. This day will then also give incorrect information about the available capacity. When scheduling forward, it would therefore make more sense to choose a start date that is in the future. In practice, this will not result in any problems, as there will often be work in progress on the current date, and it would not make any sense to reschedule that work.

Settings

Schedule production files without date

Schedule production files without date

When this option has been selected, production files without start or end date will be scheduled based on a specified start or end date. You are required to fill in a start or end date.

When this option has not been selected, and a period has been specified using the 'From' and 'To' fields, production files without start or end date will not be scheduled.

This setting will be activated automatically and cannot be changed if you make a selection by production status/date and you have not specified a start or end date.

If you have opted for a selection by production status/date and you have specified a start or end date, or if you are using a selection by production file/order, there are two possibilities:

Overwrite production file data

Overwrite production file data

If this check box is selected, Isah uses the start and end dates of the production files based on the planning of unconfirmed operations.

Schedule underlying production files

Schedule underlying production files

If this check box is selected, the production files that need to be scheduled will initially be determined by the selection. If these selected production files have any underlying production files, these underlying files will be scheduled as well. If priorities have been set for the main file, the same priorities will be used for the underlying files, irrespective of whether they have their own priorities.

Backward scheduling

Production files are back-scheduled as follows:

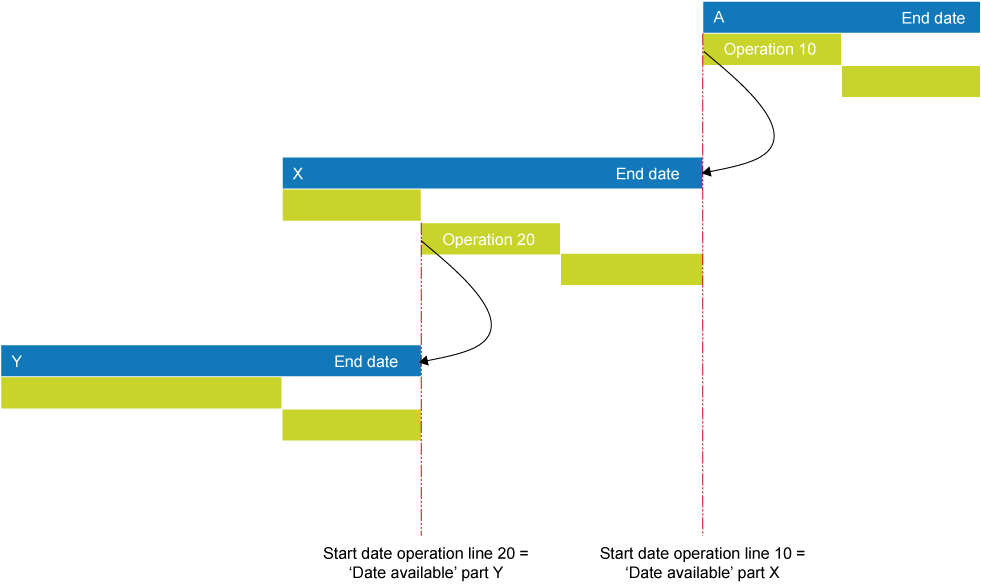

Example Backward scheduling

The start date of operation 10 in the main production file will be the date part X is required. The date required determines the end date of the production file for part X. The start date of operation 20 in the production file for part X will be the date part Y is required. The date required determines the end date of the production file for part Y. Initially, the order code of the part determines the origin type.

The start date of operation 10 in the main production file will be the date part X is required. The date required determines the end date of the production file for part X. The start date of operation 20 in the production file for part X will be the date part Y is required. The date required determines the end date of the production file for part Y. Initially, the order code of the part determines the origin type.

Scheduling forward

Production files are forward-scheduled as follows:

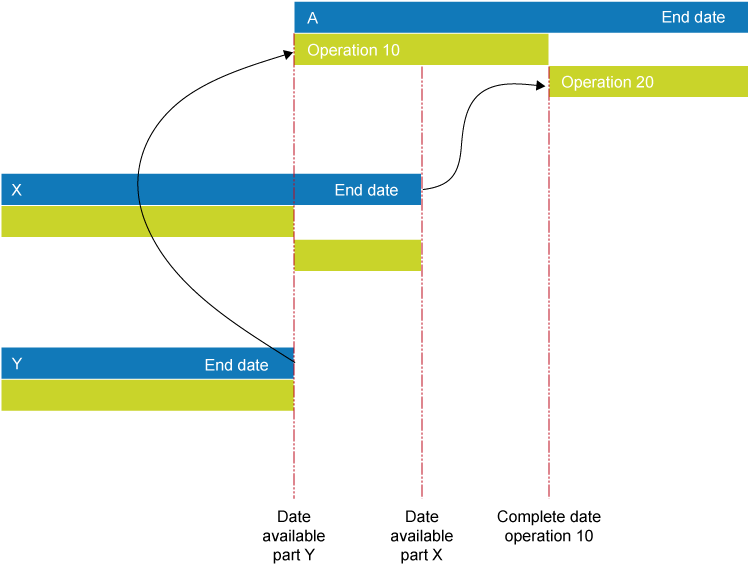

Example Scheduling forward

The start date for operation 20 depends on both the end date of operation 10 and the 'Date available' for part X. The latter of the two dates will ultimately determine the start date. Therefore, in this case, the end date of operation 10 is decisive, because it is later than the 'Date available'.

Priorities

You can assign the following priorities:

|

Production files are scheduled based on the priorities you have assigned to customers on the Customers form (in the Customers module). |

|

Production files are scheduled based on the priorities you have assigned to sales orders on the Specification tab of the Sales orders form (in the Sales module). |

|

The shipping date in the sales line (Sales module, Sales orders form, Lines button) for which the production file will be used, determines how the production files are scheduled. |

|

The status in the sales line (Sales module, Sales orders form, Lines button) for which the production file will be used, determines how the production files are scheduled. |

|

Production files are scheduled based on their end date (production modules, Production files form, Planning tab). |

|

Production files are scheduled based on the priority set in the production file (production modules, Production files form, Planning tab). |

|

Production files are scheduled based on the status set in the production file (production modules, Production files form, General tab). |

Choosing ascending or descending priorities

For every priority, you can set an ascending or descending sorting order.

Scheduling order if Ascending |

Scheduling order if Descending |

Priority 1 |

Priority 3 |

Priority 2 |

Priority 2 |

Priority 3 |

Priority 1 |

Specifying multiple priorities

It is possible to specify multiple priorities, in order to achieve a sort within a sort. If the priorities specified do not result in an unambiguous order, scheduling will take place based on ascending production file codes, or, in other words, based on the scheduling principle First Come, First Served (FCFS).

Example 1

All production files with customer priority 1 are planned in order of the shipping dates specified in the sales lines for which the production file will be used. Where production files have the same customer priority and shipping date, the production file with the highest status will be scheduled first, followed by the production file with the next highest status. Production files without customer priority will be scheduled last, based on the shipping date specified in the sales line.

Example 2

All production files with production priority 1 are planned in order of the shipping dates specified in the sales lines for which the production file will be used. Production files without production file priority will be scheduled last, based on the shipping date specified in the sales line.